Impact Driver vs. Drill – Which Should You Buy for Your Project?

What's a Drill?

The drill is a power tool that despite its straightforward and evident looks, can still be deceiving to many. Some people think that having a drill means that they can drill anything anytime. This cannot be further from the truth.

There is a good reason why drills are classified by different names. But more on this below, we separately explain the difference, pros/cons of each types of drill.

Traditional Drill

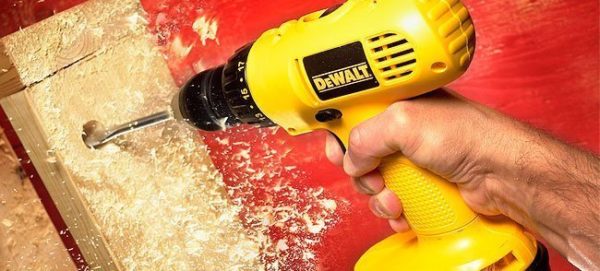

An electric drill, or commonly known as a traditional drill is a power tool that pierces holes in materials. It has a linear torque and usually comes with an average motor. Additionally, it can be used to make an electric screwdriver. The components of a traditional drill are fairly simple, but it is a powerful beast that can send a lot of torque to the drill bit. For this reason, the drill can pierce almost anything – from wood to metal (given the appropriate bit is used).

The traditional drill is the go-to power tool of almost anyone. In fact, whenever people think about drill - it is this type! It is a great general purpose drill and when used with an appropriate bit, it can drill through anything. It does so without costing a lot of money. Indeed, traditional drills are not very expensive – at least, relative to other more specialized drill types.

Pros

- Fast, powerful and efficient. They vary in size and shape, and many are 12V portable with a very lightweight form factor.

- They are ideal for loosening bolts and screws since those do not require a lot of torque.

- Can pierce many soft materials like wood with great ease. This is especially true when used in tandem with a specialized drill bit.

- Drill bits can be changed for more adapted materials. Furthermore, many traditional drill have a keyless fob mechanism that allows you to change the drill bit in record breaking time.

- Drill bits are inexpensive. There is a slew of prices and models for the drill. But most of the time, they can be had for not much.

- Not a very expensive power tool compared to other types. Due to its popularity, there is a lot of competition that helps drive prices down.

Cons

- Lacks the accuracy when used as a screwdriver. Since it drills in a linear way and there is almost no speed control, accuracy greatly suffers.

- Performance is linear and not the best for hard materials like concrete. In fact, the weak torque is not enough to pierce tough materials, even when retrofitted with more adapted bits.

Hammer Drill

The hammer drill looks a lot like the traditional regular drill, with small additions to it. It starts the same as a regular drill, but apply more pressure on the bit and it sends more juice. It is much more powerful and the drill bit pulses forward and backward so as to pierce materials harder. The main use of a hammer drill is to pierce tough material like concrete.

Pros

- Can pierce tough material. The forward and backward motion of the bit gives it an extra push into the material. Furthermore, the torque depends on the pressure you put on the tool. The more you press, the greater the torque sent. It is all on automatic.

- Easier to bore holes or drill. The weight of the tool is enough for the drill to kick in power mode and start drilling harder.

- Powerful device with great handling. Most hammer drills also sport an ergonomic design, since they are meant to have pressure applied on. They are also not the lightest of tools.

Cons

- Very dirty drill hole. Not to be used for precision work at all.

- More expensive than traditional drills. Since more work and engineering goes inside a hammer drill, it is sold at a premium price.

- Very noisy. This is mostly because of the power required to provide the torque for the bit. The hammer drill sound is reminiscent of jackhammers when in operation.

- Heavy and bulky. Not the most portable but that is because of the work they have to perform - hence beefy motors and/or battery.

- Requires more power to operate, hence portable models are not the most powerful hammer drills.

Read More: 7 Best Drill Presses - Reviews & Buying Guide

What is an Impact Driver?

Unlike other types of drills, the impact drill or impact driver works by “impact”. This means that it will automatically compensate with torque whenever it feels you’ve hit a hard drill area. Furthermore, impact drivers use an anvil system of rotation that sends force perpendicular to the bit. This makes it ideal for unscrewing bolts and screws and not so much of a driller.

The rotation of an impact driver is non-linear and can produce unpredictable results. However, as mentioned before, thanks to the anvil rotation, when used as a screwing machine it has no second since it mimics the way a person who manually screw material.

In terms of force and put in a scenario of an impact driver vs hammer drill competition, the impact driver will win in accuracy but not in speed or force. It sends less torque in small bursts at right angle to the bit. Contrasted to the impact driver, the hammer drill sends all the torque in the direction of the bit - and penetrates anything.

Pros

- Exceptional performance when used to screw or remove bolts and screws.

- Uses a quick lock chuck system that makes adding or changing drill bits a cinch

- Relatively lightweight

- More ergonomic form factor

Cons

- Stubby shape for portable models. Since the impact drivers need a lot of torque, its battery is huge and generally fitted at the bottom of the unit.

- Not suited for general purpose drilling. In fact, it should not be used for drilling.

Impact Driver vs. Drill

1. WoodWorkers Guild of America

George Vondriska of Woodworkers Guild of America pit the impact driver vs drill. The results are quite interesting. Both of the tools he used were portable ones. Not that it will make a difference.

His opinion about the drill is that it is a bad power tool to screw or unscrew. It is better for “drilling”, however. When he tried to use a drill on a screw, it didn’t go so well. But he used an interesting analogy of working on a vehicle to explain why an impact driver is better for this purpose. The gist is, by “banging” or sending small bursts of torque to the bit, the impact driver is better able to bolt or screw.

According to George, the savvy handyman will need both in their workshop, since they both accomplish different things. One is for traditional drilling, and the other is more of a bolting power tool that even has its uses in drilling.

2. Craftsman

Rob North also compared the impact driver vs drill. His flamboyant and professional video not only contains invaluable information but also a healthy dose of humor. He used a portable Craftsman drill and a portable Craftsman Impact driver for his comparison.

He clearly explains the anvil principle behind the impact driver, where it is used mostly to “twist” (his own term) the material.

Consequently, he depicts the impact driver as a screwing tool rather than a driller. That is what the drill is for. He further explains how the drill driver sends a constant torque to drill material in a linear manner.

He also succinctly ends with the conclusion – a drill driver is used to drive screws into delicate materials. With an impact driver, it is mostly for removing bolts. The only time to use an impact driver, according to him, is when you are using a spade bit to bore holes.

If you have not watched Rob North’s video about the impact driver vs drill, check it out!

3. Steve Ramsey

Veteran handyman Steve Ramsey also had an informative comparison of the impact driver vs drill. He confessed to have used the drill for years before he finally was able to get an impact driver.

He is quite categorical about it. You will need both to be the most versatile and polyvalent you can be on the workplace. He shows how the impact driver only accepts a special chuck bit so that it does not fall off when the impact driver works.

He made a nifty case study of using both the drill and impact driver to screw into wood. It clearly shows that the drill makes an ugly screwing while the impact driver softly delivers the screw into the wood.

Steve uses both in an original way. He basically uses the drill to make a hole and then switches to an impact driver to drive the screw in. The finish is definitely more professional this way.

4. Ultimate Handyman

Equally, the Ultimate Handyman highlight the difference between the impact driver and drill. He voices out his opinion quite loudly about both. He uses 12V Milwaukee drills. Right off the bat, he says that the impact driver is quite noisy.

But he goes on with the test…

And he even uses a sound meter to test the sound output of both while driving screws into wood.

The drill scores an average of 72 dB while the impact driver scores a scary 90db. Clearly, he demonstrated how noisy the impact driver is, which explains his preference for the more silent drill.

Conclusion

As we saw, there are big differences between an impact driver and a drill in most case scenarios. They look so much alike and yet are better suited for different jobs.

Ideally, most experts recommend that you use both. The impact driver is better suited for a screw/unscrew and bolt/unbolt power tool while the drill can be a little bit of everything. The drill is much more silent but at the expense of screwing in a less accurate way than the impact driver. If sound emission is an important factor for you, then you will find yourself using the drill more often. If not, the impact driver offers exceptional performance. In any case, both works wonders together.

Last Updated on August 7, 2020 by