Jointer vs. Planer: How to Choose the Right Option

When buying lumber for your projects, you can get anything from rough cuts to finely milled and ready to use pieces. But, most of the times the wood will be rough cut because the millers have no idea on what you intend to make.

And so you need to resize the lumber to suit your needs using power tools. When it comes to milling and squaring or resizing your lumber pieces, the jointer and planer are the best tools for the job.

While it is obvious, you need both the planer and jointer to get the most of rough lumber most woodworkers can only afford to get one of them first.

These power tools are expensive, and so if you are building up your toolkit, it might not be possible to get both at a go. But it is not always easy to choose what to get first.

Knowing how each of the two tools works and its capabilities should make it easy to determine which to buy first.

Jointer

When buying lumber, you will always end up with some pieces that have twisted, warped or bowed faces. While you can pay the lumberyard for face preparations, this means incurring extra cost.

The best way to give your lumber pieces that perfect edge and face or convert them into useful wood for your woodworking projects is by investing in a jointer.

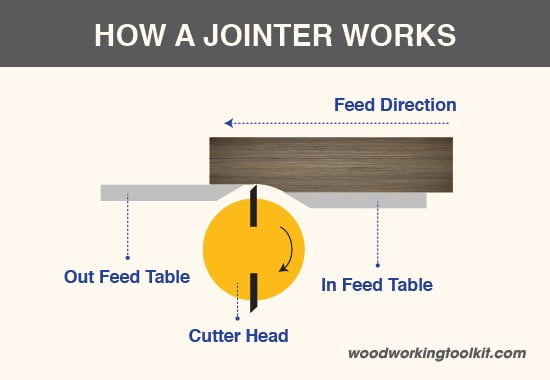

The jointer will consist of an infeed and outfeed table that will be aligned in the same plane. And there will be a cutter head with multiple knives mounted between the two tables.

For arrangement, the tops of the knives will be aligned with the outfeed table while the infeed table is lowered to a depth that should be equal to the amount of wood that you want to remove.

Passing the lumber board across the jointer and with the guard in place will remove the necessary wood to make the surface flat. The outfeed table will then support the cut lumber piece.

Also, note that there will be a fence on the jointer for guiding the lumber during the flattening and it also acts as a support for the piece. This fence is also adjustable to different angles.

Although you need both the jointer and planer to prepare your lumber pieces the job of making them flat, straight and square always starts with the jointer. And its primary task is to make the two edges of the lumber flat and square (90 degrees to one another).

Pros

- Best for flattening edges. A jointer is always the first tool to use when getting lumber pieces ready for your woodworking projects. It is the best for making the lumber boards perfectly flat, and it will also remove warps and twist to give you that square shape that you desire for your project.

- Adjustable for different angles. One of the main differences between a planer and jointer is that the latter comes with an adjustable fence that makes it possible to change the angle of the cut. It gives woodworkers the option of making 45-degree or 90-degree cuts and other smaller cuts. This feature can be quite helpful when working on molding pieces.

- Straightens the boards. Besides from flattening your lumber, the jointer is also the tool to turn to when you need to straighten the pieces and make them perpendicular. And it achieves all this at a go, so you do not need to make many passes.

Cons

- Rough sides. Although the jointer will give you flat surfaces and remove the twists and warps, the lumber pieces will still have rough faces even after passing through the machine. And so this means that you cannot get pieces that are ready for use just by using the jointer only.

- Faces not parallel. Unlike the planer, the jointer will not produce two parallel faces. The jointer will excel in making one flat face and one square edge, and although you can also get the same on the others, they will not be parallel to the first one.

Planer

Even after passing your rough lumber pieces through a jointer they might still not be ready for your projects. While a jointer makes the edges and faces flat and square, they will not be parallel, and the thickness will also not be right.

For the correct thickness, you need to pass the pieces through a planer. Also, the planer is the tool that you will need to make sure that both edges and faces are parallel to one another.

The planer will consist of infeed and outfeed rollers and a cutter head between them. The infeed rollers will grab the stock and pull it through past the rotating cutter head and towards the outfeed rollers that grab it and take it out of the machine on the other side.

When using the planer the distances between the table and the cutter head is what determines the lumber thickness that you get.

However, these machines will have a limit on the amount of wood they can remove and so in most instances you might have to make multiple passes to get the desired thickness.

Pros

- Parallel surfaces. A jointer can make your lumber pieces flat and square, but the edges and faces will not be parallel. For parallel faces and edges, the planer will be the best choice. And all you need to do is make a few passes on both sides of the pieces to make them co-planar.

- Ideal for rougher wood types. When you do not want to use pre-milled stock, or you have some rough boards a planer will be handy. As long as the boards are straight (at least reasonably), you only need to run them through the planer while taking some light passes to create some clean faces that will also be quite flat and parallel.

- Best for enhancing the thickness. Besides from producing square and parallel edges and faces a planer will also help you get the thickness that you desire. But, since the cutter head can only remove a specific amount of materials on every pass you need multiple passes to get the right thickness.

Cons

- Duplicates board defects. If your piece of lumber has a significant dip or lump on the side, it will be reflected by the planer's cutter blades on the other side of the lumber. It is because of this reason that you should only place flattened and straight boards or start by passing them through the jointer first. Failure to do so risks duplicating the board's defects and just making them thinner.

- You need to make multiple passes. When using the jointer, you will only need one pass to flatten the lumber provided you set everything up correctly. However, planers have a limit on the thickness of materials that they can remove and so in most instances you need to make multiple passes to get the thickness that you want. And this means you will spend more time working on the planer than you would on the jointer.

The Bottom Line: Jointer vs. Planer

Every seasoned woodworker seems to have a particular opinion when it comes to choosing between the jointer and planer. But, from my experiences, I find the planer more useful around the workshop than a jointer.

If you want to buy one before the other, my advice would be to start with a planer. And the reason for this is that most of the lumber that you will buy will be pre-milled and hence somewhat flat and acceptably straight.

With a planer, you can then run a few passes on each of the faces to get some parallel sides with the exact thickness that you desire. Although the planer will not square the edges, you can then use a circular saw or table saw for this as they will produce some reasonably acceptable outcomes.

You can do a lot more with a planer than you would with a jointer alone and so it is always a great idea to get it first before adding the jointer to your tool collection later down the road.

However, if your primary concern is always getting some flat and square lumber pieces or most of your projects require such lumber, then a jointer will be the best option.

Jointer & Planer Combination

If like many other experienced woodworkers and DIYers you prefer to have the lumberyard do minimum surface preparations on your boards, you will need both the jointer and planer.

When you buy these rough boards, you can save some significant amount of cash, but the pieces that you need to make your cabinets and other furniture will be ‘inside’ the boards.

What this means is that you will have to machine the boards with both the jointer and planer to get the perfect pieces for your projects.

Here you will start by passing the bowed, warped or twisted board through the jointer to get some flat surfaces and edges. You can then pass the board with the new flat surface through the planer to make the top surface parallel to the flat bottom.

Passing the piece through the planer also ensures that you get a flat piece with uniform thickness throughout that is ready for use.

The bottom line is that although you might need to buy one of the two tools first due to the cost, you will need to own both at some point as they combine well to make lumber preparation less tedious for you.

Best Jointers

Cutech 40160H-CT 6-Inch Bench Top Spiral Cutterhead Jointer

The Cutech 40160H-CT is designed for both novice and professional woodworkers in mind as it has what it takes to cater for both groups.

This jointer uses a 10-Amp motor that generates more than enough power. And it comes with a redesigned spiral cutterhead that produces an exceptional finish while also minimizing tear outs.

It comes with a one-piece adjustable fence that is 4 3/8 inches high, and you can tilt it from 90 to 135 degrees and do it with ease. Also, it uses some cast infeed and outfeed tables that you can level quickly.

This fantastic jointer has a 6-inch width capacity and a total table length of 30 inches to make it suitable for use with longer boards.

Cutech 40160H-CT is also a tough jointer to withstand regular worksite abuse, and you can move it from one place to another quickly.

Porter Cable 6-Inch Variable Speed Bench Jointer

For the woodworkers that are looking for an affordable jointer to add to their toolkit this one from Porte Cable will be an excellent choice.

It is a variable speed 6-inch bench jointer with a powerful motor that is capable of speeds of between 6,000 to 11,000 RPM for top-notch performance and excellent control.

This jointer has a two-knife cutter head and with the jackscrew knife leveling arrangement to make knife replacement and adjustment easy.

And the fence is center mounted to ensure that the material gets the necessary support throughout the cut for accurate jointing. The extra large table is also a great addition as it provides ample support for the stock and sufficient workspace.

Best Planers

DeWalt DW734 15 Amps 12-1/2-Inch Benchtop Planer

DeWalt makes their model DW734 planer for the seasoned woodworkers that are ready to spend more on a highly efficient and reliable planer.

The powerful planer runs on a 15-Amp motor that is capable of generating speeds of up to 20,000 RPM for handling large cuts on wide materials with ease.

And the cutterhead has three knives that have a 10,000 RPM speed, and they are also easy to change.

The two-speed gearbox on this planer makes it easy to change feed speed and to optimize the cuts per inch.

This planer uses 19-3/4 inches cast aluminum that is highly rigid to make it sturdy. And there is also a fan-assisted chip ejection that will help to exhaust chips out of the machine.

Wen 6550 12.5-Inch 15A Benchtop Thickness Planer

Wen 6550 is a relatively affordable thickness planer that will help you give those rough and worn wood pieces a smooth finish to make them ideal for your projects.

The planer uses a 15-Amp motor that combines with a two-blade cutting system to provide an impressive 18,000 cuts per minute. And it comes with a granite table that will provide a sturdy and non-marring surface for the lumber pieces to move over.

You can use this thickness planer to plane boards that are up to 6 inches thick and both the infeed and outfeed tables are foldable to support larger stocks.

This Wen planer uses a tri-roller feeding system that helps to minimize snipe, and it comes with a rubber handle to help you adjust the height comfortably.

Reference: wwgoa, thewoodwhisperer, popularwoodworking, rockler, woodworkweb

Last Updated on August 30, 2021 by Tom Bradly