All You Need to Know About The Types of Joints In Wood Work

No matter what type of woodworking project you’re working on, you’ll need to use joints to hold the pieces of wood together. There are many types of joints in woodworking, and each has its advantages and disadvantages.

This article will discuss the most common types of joints and explain how to use them effectively.

15 Common Wood Joint Types

In woodwork, you can use several different joints to secure pieces of wood together. The most common types of joints used in woodwork are:

1. Butt Joint

The butt joint is the simplest of all joints, and it’s straightforward to create. To make a butt joint, you just place two pieces of wood side by side and mark where they meet on both pieces.

Then you cut along your marks so that each piece of wood has one flat surface and one cut surface (similar to a beveled cut). When you put the pieces of wood together, their flat surfaces should be touching.

This type of joint is usually used when gluing two pieces of wood together (so that they can dry without moving about), when making boxes or crates, and in window frames.

2. Miter Joint

To make a miter joint, you need to place two pieces of wood at a 90-degree angle to each other and mark where they meet.

Next, cut both pieces of wood on their marked lines so that one piece forms a right angle while the other is cut diagonally.

This type of joint can be used when cutting corners to make frames or when attaching a piece of wood at an angle.

3. Dovetail Joint

To make a dovetail joint, you need to cut two pieces of wood so that their ends form pins and tails.

Then, hold the pieces together by tapping them with a hammer or using clamps until they are secured in place.

This type of joint is often used for drawers, boxes and chests, as well as to hold the frame of a door together. Many different tools can be used to make this type of joint.

4. Rabbet Joint

To make a rabbet joint, you need to cut two pieces of wood so that they fit together like a T, with one piece forming the vertical edge (the side of the "T") and another piece forming the flat surface.

This type of joint is often used to attach shelves or side panels in cabinets, or can be used to make drawers. Many different tools can be used to make this type of joint.

5. Tongue And Groove Joint

A tongue and groove joint is formed when you cut one piece of wood with a groove that matches the shape of another piece's tongue (or "hook"). When you put the pieces together, they fit tightly.

This type of joint is often used when you want to join boards together; for example, you can use it when making laminate flooring or skirting boards. It can also be used when fitting onto stairs or in other situations where the joint has to fit tightly together.

6. Coped Joint

A coped joint is made when one piece of wood is cut so that it forms a shape similar to the other piece of wood. So, if you want to join two pieces of roundwood together, for example, you could cut one board into a quarter circle and then fit the other board into its beveled edge.

This type of joint is often used when you want to connect two boards together at an angle (such as the top of a frame).

7. Mortise & Tenon Joint

A mortise and tenon joint is made when you add a tenon (a protrusion that fits into another part) to one piece of wood, and then add a mortise (a cavity in the other piece to receive the tenon) so that they fit together.

When you put the pieces together, you’ll often need to tap them with a mallet or hammer to ensure that they are firmly fixed.

This type of joint is often used in the construction of a frame, to join legs, and also when making drawers (where you might need two such joints). It can also be used to add wooden handles, such as in cutting boards.

8. Half-Lap Joint

A half-lap joint is made when you cut one board so that its width forms a half-lap on the other board. You next place the pieces together and fit them tightly so that they do not move or slip around.

This type of joint is commonly used in skirting boards. It can also be used where one piece needs to be fixed at a slight angle to another, or when you want to fix a board around a corner.

9. Biscuit Joint

To make a biscuit joint, you cut two pieces of wood so that they fit together like a T, with one-piece forming the vertical edge (the side of the "T") and another piece forming the flat surface.

To fix them together, you need to cut a small piece of wood (called a biscuit) and insert it into the two pieces of joinery.

This type of joint is often used when making cabinets or drawers, as it allows for flexibility in the width of boards and can be fixed using glue alone.

10. Dado Joint

To make a dado joint, you need to cut one piece of wood so that it forms a groove and the other piece of wood fits into it.

This type of joint is often used for skirting boards where you want to fix one board on top of another, for example.

It can also be used when joining large pieces of wood together in order to create a larger flat surface onto which to attach something else.

11. Pocket-Hole Joint

To make a pocket-hole joint, you need to drill a hole in one piece of wood and cut it so that the other piece fits snugly into it.

This type of joint is often used when joining two boards together at 90 degrees so that you can screw them into place. It's also often used in children's furniture.

12. Dowel Joint

To make a dowel joint, you need to drill holes in both pieces of wood and insert wooden pegs (or dowels) into them.

This type of joint is often used when fixing furniture legs onto their frames (such as table legs). It can also be used to secure door handles or knobs on cabinets.

13. Box Joint

A box joint is made when you add a groove to one piece of wood and then add a tongue or protrusion to another so that they fit together.

This type of joint is often used in drawers where the pieces have to be fixed at 90 degrees. It can also be used when fixing leg plates onto desks or other types of furniture.

14. Bridle Joint

A bridle joint is made when you add a smaller piece of wood at 90 degrees to one larger piece.

This type of joint is often used in the construction of frames where you want the smaller piece to fit into a space between two boards.

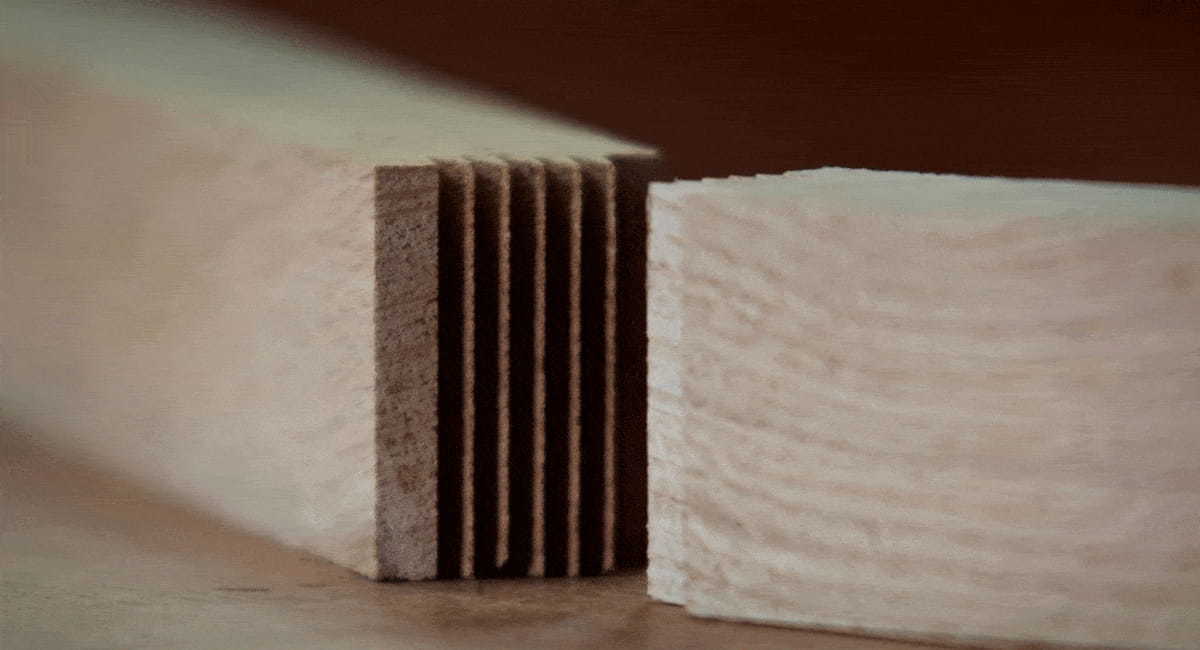

15. Finger Joints

Finger joints can be made at home using a miter box and a hand saw. To make a finger joint, you need to cut one piece of wood so that it forms a T. The other piece of wood is the same width as the edge.

This type of joint is often used when making light furniture such as chairs, toys or shelves. It's also useful in making repairs where boards are not connected to the frame but are only touching the frame.

Why Are Woodworking Joints Important?

Woodworking joints are important because they allow pieces of wood to be attached together without nails or powerful screws. This allows you to create a variety of different wooden objects, from tables and chairs to cabinets and bookshelves.

There are a number of different types of joints that can be used for joining boards which depend on the type of object being made, the type of wood used, and the preference of the person making it.

Joints also allow for flexibility in building, which is often important if you're making objects with pieces that expand or contract (such as furniture that expands or contracts with heat).

FAQs About Types Of Joint In Wood Work

Which Type Of Wood Joint Is The Simplest?

The simplest type of joint is a butt joint, where the boards are placed side by side and joined together. It's useful because it can be made quickly with minimal equipment and it doesn't require any special skills.

Which Type Of Wood Joint Is The Strongest?

Woodworking joints don't add much strength to the materials they're joining, but you can make the joint itself stronger by using glue and screws. The addition of glue and screws makes it more difficult to disassemble the joints, which is often what you want for heavy objects like furniture.

What Is A Cogged Joint?

A cogged joint is where a piece of wood has notches and ridges cut into it, which allow that board to be connected with another board. It's used when you want to create specific looks or effects in the objects being made (such as creating a curve).

What Is A Haunch In Joinery?

The haunch is a section of molding that sticks out past the surface of a piece of wood. It can be used to cover gaps in joints and often gives objects a more elegant appearance.

Final Thoughts On Types Of Joints In Wood Work

This article has gone over the different types of joints in woodworking, how they work, and why they’re important for making objects.

We’ve also described some common joints that are used when making light furniture with boards, but there are many other types of joints in wood work that are useful when building with specific materials.

Hopefully, this post has given you an idea of what joints are used for and why they're important.

Finally, if you want to learn more about the different tools needed when making things with wood, read about 51 Free Portable Workbench Plans to Get You Started Woodworking & Types of Saws for Woodworking.

Last Updated on April 30, 2022 by Tom Bradly