Polycrylic vs. Polyurethane: Ultimate Guide

No woodworking project or piece is complete without applying a durable topcoat or finish. But for many DIYers and woodworkers, the problem comes when they have to choose what type of finish to use.

In most instances, you will need to pick between polycrylic and polyurethane. And no, they are not the same thing even though they might sound like it. They are, however, the most popular protective finishes, although there are also many other options out there.

Both polycrylic and polyurethane are essential when it comes to finishing your pieces, whether you are working on a table and chair set, a bookcase, or some kitchen cabinetry. Not only do they provide that durable protective coat you need, but they also offer an aesthetically pleasing shine.

You will generally use one of these two finishing options when you are going for the natural look with your woodworking. (And I hope you agree that most pieces of wood just look better when they keep their natural grain rather than getting painted over with some garish color.)

For some workpieces, you can even use both. However, for many projects, you will only need to pick one. When you head over to the hardware store, however, and come upon these two different products, you don’t want to pick the wrong one for the finishing job you have.

The only way to ensure that you make the right choice is by understanding the best uses of polycrylic vs. polyurethane, and also the pros and cons of using it on your workpieces.

Polycrylic

Tables, chairs, entertainment centers, and consoles are some of the most popular DIY projects. And since most will take a lot of effort and significant time to finish, you will also want to give them the best topcoat.

When it comes to finishing these common DIY projects, polycrylic is what most DIYers will use. For many, this is because it provides a transparent finish, hence ensuring that it does not change the appearance of the stain or wood.

Polycrylic is a handy water-based sealer. Its protective coat will be useful for a variety of applications for DIYers and woodworkers. Also, it comes in various finishes such as satin and gloss.

When using polycrylic, you get the freedom to apply it with either a spray bottle or roller depending on the piece you are working with, and so it makes it easy to reach tight corners. Spraying or applying it evenly on finished projects is also easier because of this versatility of use.

Most DIYers prefer to use polycrylic to add that touch of stylish beauty to interior woodwork pieces – from living room furniture to doors, tables, and cabinets.

Additionally, it is generally the best choice of finish or topcoat when you are working with light wooden surfaces such as maple and birch. The fact that it is a clear finish with no tint is what makes it ideal for these light-colored surfaces. It will not change the appearance of the piece.

When using water-based stain for your wood pieces, polycrylic will be a much better option than oil-based polyurethane. Unlike polyurethane, you do not have to wait a long time for polycrylic to dry. Because it offers a quick-drying finish, this can speed up your project timeline significantly.

On the other hand, polyurethane will take at least a few hours to dry, which means that your woodworking project has to be left alone with no disturbances to ensure a good, even finish.

Also, in most cases, polycrylic is cheaper than polyurethane, so it is a good choice when cost is a vital factor. If you’re working on a budget and you need a finishing coat for your DIY woodworking project, polycrylic’s inexpensive cost and ease of use are something you should keep in mind for a more convenient and cost effective experience.

Finally, polycrylic is also easier to clean up than polyurethane. Because of its water-based elements, your tidying-up process afterward is more straightforward.

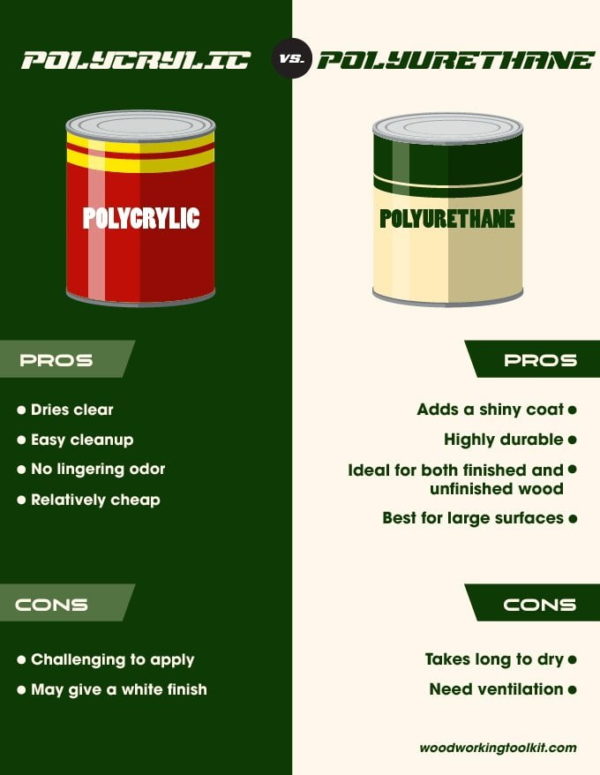

Pros

- Dries clear. With polycrylic, you always get a clear finish. This is an important factor when working on surfaces that have a naturally light shade such as birch, maple, and ash. Polycrylic preserves the appearance of the surface, unlike polyurethane, which will have a slightly yellow finish once it dries.

- Easy cleanup. The ease of cleaning the water-based polycrylic finish is one of the things that make it a fantastic choice. Unlike polyurethane, you will only need soap and water to clean the surface.

- No lingering odor. When using polycrylic, you will not have to leave the windows open for hours because it does not have any lingering odors. This can be a significant advantage when working indoors, especially if you or someone in the household is sensitive to chemical smells.

- Relatively cheap. If you compare polycrylic to other finishes such as polyurethane, it is relatively less expensive. Because it is water-based, it is cheaper to manufacture than oil-based polyurethane.

Cons

- Challenging to apply. The low viscosity of polycrylic makes it a little harder to spread than polyurethane. In other words, it has a rather runny consistency, which can especially prove challenging when you are working on vertical surfaces. Also, compared to polyurethane, it dries very fast, so it can be a challenge to apply it evenly on large surfaces before it begins to dry.

- May give a white finish. Contrary to what most people think, polycrylic is not completely transparent. It can leave a milky-white finish if you apply it too thickly to a surface. This problem is common when working on surfaces with dark-colored paints.

Polyurethane

Some of the woodworking pieces that you make will end up in high-traffic places or exposed to elements such as heat. With such items, you’ll want to have a hard finish to make them long-lasting.

When you want to give a hard finish to your tabletops, hardwood floors, and other pieces that will need to absorb a lot of abuse, polyurethane is always the best choice.

Unlike polycrylics, polyurethane is available in both water-based and oil-based forms. To make it clear, polyurethane is the more versatile of the two, as you can use it on a variety of surfaces. The water-based polyurethane is appreciated for being less toxic, low in odor, and quick-drying.

Oil-based polyurethane might not dry as fast as the water-based form or its polycrylic counterpart, but it provides a more durable finish than both. And it can also handle extreme heat.

Polyurethane has the same properties as melted plastic. This means that once it hardens, it will form a strong protective shell over the wood surface. Unlike polycrylic, this finish is hard to remove and it will last for a long time.

The shine that polyurethane gives your wood furniture is also hard to get when using polycrylic and other finishes. For this reason, it is always the best choice when you want to provide pieces with a shiny and expensive look.

The hard shell that polyurethane creates is also scratch-proof, which further preserves the appearance of your woodworking pieces for a long time. The added durability will ensure that your projects will look their best for years to come. This also makes it easier to clean them because of the water resistant nature of oil based polyurethane

Water-based polyurethane will be best for picture frames, side tables, desks, and bookcases; the oil-based form is excellent for hardwood flooring, kitchen tables, and any surface that might be prone to getting wet such as outdoor furniture.

Read More: Lacquer vs. Polyurethane

Pros

- Adds a shiny coat. If you are looking for a finish to give your furniture that rich and glossy look, polyurethane is an excellent choice. Unlike polycrylic, the oil-based polyurethane will always leave wood surfaces with a shiny coat.

- It will also not change the color of the finished wood. If you’re working with light woods, this is especially important as the color theme of your room wouldn’t be affected by any kind of a tint from the clear material and finish of polyurethane. This makes it better than polycrylic because polycrylic material can leave a white tint on your projects.

- Highly durable. It is a fact that polyurethane (and more so the oil-based form) will take more time than polycrylic to dry. However, once it dries, it will create a robust shell over the piece, which offers great longevity. To make things even better, this hard shell cannot be easily scratched or marked. It will be a long time before you need to redo the finishing when you use polyurethane. The durability will also provide resistance to water damage, something that’s quite common when you’re working with wood.

- Ideal for both finished and unfinished wood. In most cases, polycrylic will be handy when dealing with softwood. However, with polyurethane, you can use it to finish both finished and unfinished wood, and this makes it quite versatile.

- Best for large surfaces. The slow-drying nature of polyurethane makes it perfect when you are working on large surfaces. When you’re using a large brush to apply polyurethane on wood, you’ll get a proper, even finish because one portion won’t dry off before the other. This will ensure that you don’t have to worry about some sections drying before you finish applying finish to the entire piece, a problem that could otherwise result in an inconsistent appearance.

Cons

- Takes a long time to dry. If you are working on tight time frames, polyurethane might not be your ideal finish as it takes a long time to dry. Also, once it dries, the curing process takes even longer. If you’re on a time constraint and you need to finish off a project quickly, polyurethane shouldn’t be your first choice for a finishing coat.

- Needs ventilation. When using oil-based polyurethane, you will need to apply it in a room with enough ventilation. This is not only because of the odor it produces, but also because it is a toxic and flammable finish.

- Polyurethane is relatively more expensive than polycrylic. If you’re working on a budget, you might have to consider this factor as polyurethane might put a bigger dent in your wallet than polycrylic would.

- Difficult to apply. While polycrylic can be used in the form of a spray and can be easily applied to right corners, as well as large surfaces, polyurethane is only suited to larger surfaces and can be quite a hassle to apply to smaller projects.

The Bottom Line

If you a seasoned woodworker or DIYer involved in different kinds of projects or you enjoy building a variety of things with different types of wood, it is a good idea to have both polycrylic and polyurethane on hand.

But, if you want a topcoat that is fast drying and provides a transparent finish for your interior wood pieces, polycrylic will be the best option. It is also the best finish to get when the cost is a determining factor as it is more affordable than polyurethane. which makes it a great fit for people who are working on a budget.

If you want something that provides a more durable and scratch-proof finish, polyurethane is the best choice.

Polyurethane is also the better option when you are working with both finished and unfinished wood and pieces that will have to face extreme heat and a lot of traffic.

The bottom line is that both the finishes are ideal depending on the kind of woodworking that you’re into.It really depends on the project you are doing, so the most ideal option is to have both around. After all, you cannot be sure when you might need to use either.

Finally, remember to always use safety precautions as you work. When using polyurethane, work in a well-ventilated space and wear a facial covering, if needed. Also, ensure that you properly dispose of any leftover cans or cleaning material such as wiping cloths due to its flammability.

Working in a non ventilated space with this material can release toxic fumes that might cause damage to your lungs if breathed in in large quantities. Taking the right safety measures and precautions will ensure that your woodworking project will look its best while also keeping you safe.

We hope that this article about polycrylic vs. polyurethane has helped you make an informed choice about which of these two options is the right fit for you. Please leave a comment if you have any questions or suggestions on which topics you want us to cover next.

We have a large number of articles, reviews, and buying guides for woodworking on our website. If you’re a budding woodworker and you’re interested in similar topics, feel free to check them out, as well!

Reference: AnaWhite.com, Diynetwork.com

Last Updated on August 29, 2021 by Tom Bradly