6 Best Dovetail Jigs – Reviews & Buying Guide

There is a tool for everything that you might need to do in the workshop. Whether you want to cut a piece of stock, sand or even join it to another, there is a tool that can make the task quick and easy.

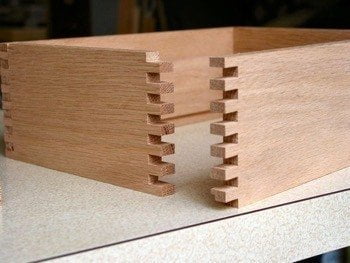

When it comes to making joints, the dovetail joint is one of the most popular options as it is not only super strong but is also very appealing aesthetically. And to make this joint, you need to have a dovetail jig.

While it is possible to make dovetail joints by hand cutting the stock, this takes a lot of effort and only highly experienced woodworkers can create perfectly fitting tails and pins.

The dovetail jig features some guide fingers to direct your router when removing material to make a joint, and they can either be fixed or variable/adjustable.

Dovetail joints provide incredible tensile strength and they are popular when making furniture and cabinet drawers. Woodworkers and hobbyists also love them for their beauty.

While a dovetail jig saves you the effort and time it takes to create the joints by hand it is still important to pick the best dovetail jig. And for this to be so you have to consider factors like capacity, versatility, price, and ease of use.

You can also read other product reviews such as dowel jig, pocket hole jig

6 Best Dovetail Jigs - Reviews

Image | Product Name | Capacity | Rating | Current Price |

|---|---|---|---|---|

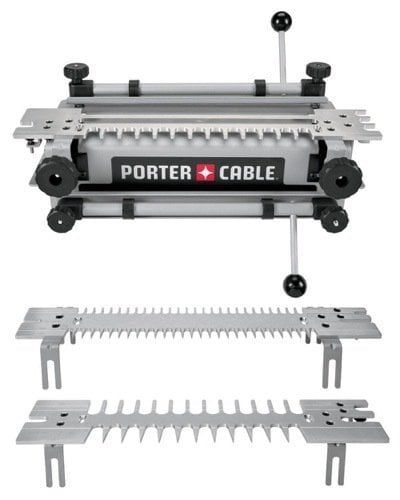

| 1. Porter-Cable 4216 Super Jig Dovetail jig | 12 in | 4.5 | |

| 2. Porter-Cable 4212 Deluxe Dovetail Jig | 12 in | 4.4 | |

| 3. Porter-Cable 4210 Dovetail Jig | 12 in | 4.1 | |

| 4. Keller Dovetail System 135-1500 Journeyman Dovetail Jig | 15 in | 4.2 | |

| 5. Leigh Super Dovetail Jig | 12 in | 4.7 | |

| 6. Leigh D4R Pro Dovetail Jig | 24 in | 4.3 |

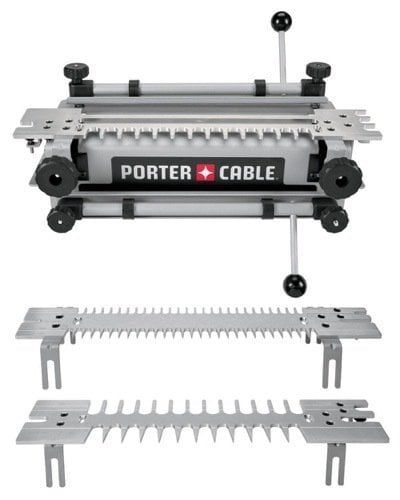

#1. Porter-Cable 4216 Super Jig - Dovetail jig

Editor's Rating:  (4.5 / 5)

(4.5 / 5)

Porte-Cable is famous for their high-quality power tools, but the company also makes some of the best performing dovetail jigs.

The relatively affordable 4216 model will help you cut all types of dovetail joints with the exception of the variable dovetails as it has some fixed guide fingers.

It also includes a mini template kit to make miniature dovetails possible. But the quick and easy set-up is what seems to impress most woodworkers as it makes the jig easy to use even for beginners.

The machined aluminum template ensures that you get superior cutting accuracy and it is also sturdy enough for long-term durability.

The template also has some alignment aids which is what allows for the quick and easy set-up. And there is also a router bit gauge that makes it possible for the woodworker to set the depth without making any measurements.

Pros:

Cons:

[su_asin asin="B000HGL59M"]

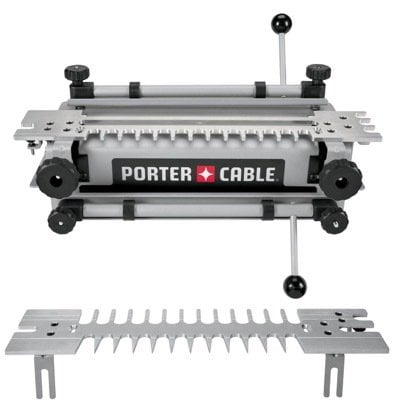

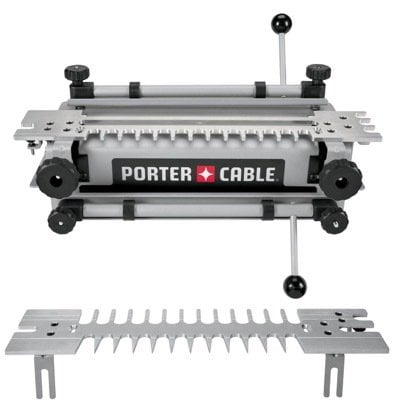

#2. Porter-Cable 4212 Deluxe Dovetail Jig

Editor's Rating:  (4.4 / 5)

(4.4 / 5)

Porter-Cable 4212 is another great dovetail jig that will be great to have in the workshop. It is one of the cheapest on our dovetail jig reviews and you can use it to make a variety of joints.

Like most other Porte-Cable dovetail jigs it features a solid construction with a durable and single-piece steel base that will require no assembly.

The jig will clamp or bolt to your workbench directly to make it even more convenient. And it will accommodate stock that is between 1/4 and 1-1/8 inches in thickness.

There are also template alignment aids and the handy router bit depth gauges on this jig that make it easy and quick to set up. Also, the depth gauges eliminate the need for measurements and hence further speeding your projects.

When you buy this useful Porter-Cable jig, you will get a couple of carbide-tipped bits and also two each of the template guides and lock nuts.

Pros:

Cons:

[su_asin asin="B0006AAS8S"]

#3. Porter-Cable 4210 12-Inch Dovetail Jig

Editor's Rating:  (4.1 / 5)

(4.1 / 5)

If most of your projects entail cutting sliding and half-blind joints the Porter-Cable 4210 will be a great dovetail jig for you. And it is also the cheapest model on our list.

Although it is not as versatile as other Porter-Cable dovetail jigs, it is still a high-quality model that will be useful to have in the workshop.

Setting it up should be quick and easy as it also has the template alignment aids. Also, setting the depth is quick, and you will also not have to worry about accuracy thanks to the router bit depth gauges.

The machined aluminum template is highly durable and also provides superior cutting accuracy. This dovetail jig is built with endurance in mind, and it will handle stock that is up to 1-1/8 inches thick and 12 inches wide.

Also, Porter-Cable makes it with beginners in mind as it also comes with an easy to follow manual that has some clear instructions for all the applications.

Pros:

Cons:

[su_asin asin="B0006AAS8I"]

#4. Keller Dovetail System 135-1500 Journeyman Dovetail Jig

Editor's Rating:  (4.2 / 5)

(4.2 / 5)

If you deal with wide stock on your projects, the Keller Dovetail System 135-1500 is the perfect dovetail jig for making joints. It comes with a 15-inch template that will accommodate any material width.

The template is also highly durable as it is precision-milled from a phenolic plate. And it comes in a back to back model that will allow it to handle the material thickness of between 1/8 and 3/4 inches.

This model is the best on our dovetail jig reviews for beginners and hobbyists as it has a simple design that makes it one of the easiest to use. It is hard to go wrong with it even if you are using a dovetail jig for the first time.

And although there are several joints that you can make with this jig, it seems to excel in cutting through and box joints.

The jig will come with everything that you need including a straight bit and standard dovetail bit and all you will need to do is make a support board.

Pros:

Cons:

[su_asin asin="B000022420"]

#5. Leigh Super 12-Inch Dovetail Jig

Editor's Rating:  (4.7 / 5)

(4.7 / 5)

The Leigh Super 12-inch dovetail jig is highly versatile and produces a precision that very few others can much. And you can use it to make almost all kind of dovetail joints.

It will accept boards that are up to 12 inches wide, and it will include three router bit options for cutting them.

The one-piece fingers on this jig are infinitely adjustable, and they are one of the features that make this a versatile dovetail jig. And so, whether you want to make some simple sliding joint or even box joints, you can do it quickly and with minimal effort.

The fact that this super 12-inch dovetail jig will not limit you to one bit or one depth cut make is a great addition to your toolkit.

And to make things even better it will come with some easy to use clamps that will help to keep the workpiece in place to increase the precision of the cut.

Pros:

Cons:

[su_asin asin="B01M08SK7L"]

#6. Leigh D4R Pro 24-Inch Dovetail Jig

Editor's Rating:  (4.3 / 5)

(4.3 / 5)

The tough and high-quality Leight D4R Pro 24-inch is designed to solve your dovetailing problem. It not only makes a variety of dovetail joints but also makes everything easy and quick.

This fantastic dovetail jig is machined from a single piece of aluminum that makes it hard and durable enough, and it will be a long time before you need to replace it. And it also has machined-in sidestops for aligning the boards.

With this dovetail jig, it is possible to route through materials that are between 1/8 and 1-1/4 inches thick. The user guide explains in detail how to work with thin materials which seems to be problematic for many woodworkers.

Leigh D4R has an efficient tool-free clamping system that includes some spring loaded clamping bars that will make securing the workpiece a quick and simple operation.

This dovetail jig uses some infinitely adjustable guide fingers that make it possible to create virtually any dovetail pattern that you want. Also, it will make any size of pins and tails.

Pros:

Cons:

[su_asin asin="B001ANMD7Y"]

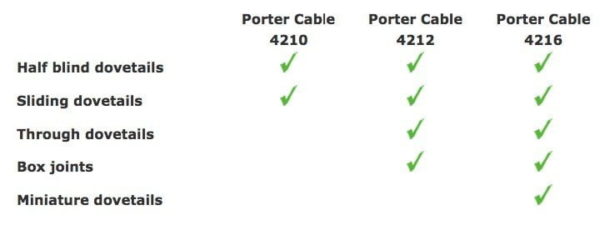

Porter-Cable 4216 vs. 4212 vs. 4210

Porter-Cable makes some high quality, reliable and highly efficient dovetail jigs and you can always trust them to have something suitable for your projects.

Their three common dovetail jig models 4210, 4212 and 4216 are designed to cater to the needs of different woodworkers. And they will not only differ in price but also in the joints that they can create.

The Porter-Cable 4210 is the most basic dovetail jig as it only cuts half blind and sliding dovetails. Porter-Cable 4212 will cut both the half blind and sliding dovetails and also through dovetails and box joints.

The Porter Cable 4216 is the most versatile dovetail jig among the three as you can use it cut the four common types of dovetail joints (half blind, sliding, through, box joints) and also miniature dovetails.

Fixed vs. Variable Dovetail Jig

As you are shopping for a dovetail jig for your projects, one of the first and most important decisions that you need to make is whether to buy one with a fixed or adjustable finger template.

If you already have a dovetail jig or are a seasoned woodworker, this should be an easy decision because you already know what works well for you. But for most woodworkers, choosing between a fixed and variable finger template is not always easy.

However, it is vital to make this decision at the onset or when buying as it is not possible to upgrade or convert a fixed finger jig into a variable one.

Fixed Dovetail Jig Template

The fixed dovetail jig template is the older of the two types, and they are the kind that is machined or curved out of a single block of aluminum.

This jig template will feature some equally spaced guide fingers for the pins and tails. You cannot adjust the position of the fingers as they are fixed, and so all the pins and tail that you will make with the jig are always the same size and with an equal space between them.

Pros:

Cons:

Variable Dovetail Jig Template

The variable dovetail jig template builds on the flaws of the fixed finger template jig. And it will consist of some moveable guide fingers that slide along the supporting bar.

The movable guide fingers on this jig template mean that you can adjust both the width of the pins and tails and their spacing.

This jig template makes it possible to customize the look of your dovetail joints to get an almost similar appearance to what you would get from the hand cut dovetails.

Pros:

Cons:

When it comes to picking between the two dovetail finger templates, your projects and budget should guide you on what to pick.

If you want something cheap for cutting some simple and basic dovetail joints, the fixed finger template will work fine. It is also the best choice when you use a dovetail jig on rare occasions.

For the seasoned woodworkers that make a lot of dovetail joints, value the appearance of the joint or want something unique that looks like it is hand cut and are ready to pay more, the variable dovetail jig is a great choice.

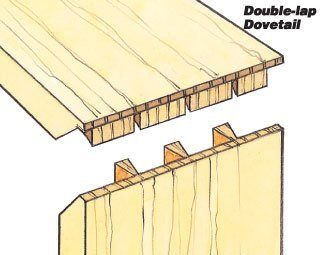

Types of Dovetail Joints

The kinds of dovetail joints that you intend to make should also help you pick the right dovetail jig for your workshop. And so it is always a great idea to understand some of the most common types of dovetail joints.

The following are the 4 common types of dovetail joints and also what many jigs will cut.

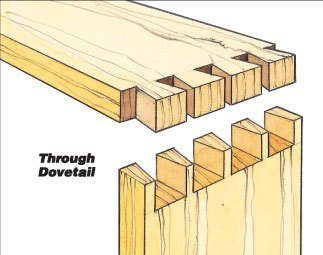

#1. Through Dovetails

The through or plain dovetail joint is one where the tail sockets are cut all the way through leaving the end grains on both boards visible once you assemble the joint.

This joint is best for box construction where the strength of the connection is more important than the ends of the tails being visible. And it can also be a very attractive joint when you use two contrasting blocks of wood.

#2. Sliding Dovetails

When you need to connect two pieces of stock at a right angle, the sliding dovetail is the joint that you have to make. And it will consist of a single tail cut on one board's edge and a corresponding pin slot on the other board for it to slide into.

Sliding dovetails provide interlocking strength to make it hard to pull out the tail board straight out from the pin slot.

The strength of this joint makes it ideal for attaching legs to a pedestal table or shelves to cabinet sides.

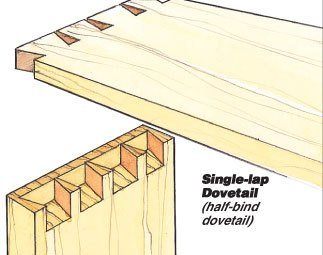

#3. Half-Blind Dovetails

Half blind dovetails are what you need to turn to when you do not want the end grain to be visible from the front of the piece. And as the name suggests, half of the joint is not visible.

Although still not quite as strong as the through dovetail, the half-blind is still quite useful in attaching drawer fronts, and anytime when you do not want your joint to be visible from the front.

#4. Box Joints

Some projects will require you to make a strong joint, but the complicated nature of the other dovetails joints means that they might not be an option. For such projects, a box joint is the best alternative as you can also make it with a dovetail jig.

A box joint might be weak (than the through and half-blind joints) and not as attractive as the other dovetail joints but it is still handy for various projects. In definition, the box joint is a dovetail with square pins and tails.

#5. Variable Dovetails

Variable dovetails are what you get when using the variable or adjustable finger template dovetail jigs. And they are just different size dovetails in one piece of stock.

This joint is great for crafts where the appearance of the joint matters, and for a project where you want to make the dovetail appear hand cut.

#6. Miniature Dovetail

Miniature dovetail joints are handy when dealing with small pieces of stocks. And as their name suggests, they are just miniature versions of the through or half-blind joints.

This dovetail will consist of several tiny tails and pins, and if you cut them right they can create a super strong joint that will be perfect for making small size furniture.

How to Buy the Best Dovetail Jigs

The dovetail jig is handy to have in the workshop when you want to make some quick and strong joints. However, there are plenty of options from different brands to pick from in the market.

Picking the right dovetail jig for your projects requires you to understand your needs or the project that you do often and the capabilities of the jig.

But to make sure that you choose the most useful dovetail jig for your workshop, you should keep the following points in mind when shopping.

#1. Capacity

Capacity is one of the first things to consider when shopping for a dovetail jig because you want something can handle all your projects.

Most dovetail jigs can handle 12-inch components, but if you think that you will need to deal with larger materials than this in your future projects, you should go for a jig with more capacity.

#2. Versatility

Versatility is another crucial factor to keep in mind when shopping for a dovetail jig. But, this will depend on the kind of projects that you do and those that you might have to do in the future.

And when it comes to the versatility, you need to consider the type of dovetail joints that your jig can cut.

The best dovetail jigs will cut all the basic dovetail joints which are through, half-blind, sliding and the variable joint. But the more the joints that the jig can make the better it will be as it will be more useful in the workshop.

#3. Ease of Use

You do not want to waste a lot of time setting up your dovetail jig and so whatever you buy should be easy to set up and use

The fixed dovetail jigs are the easiest to set up. Also, using one should not take a lot of effort. However, the variable jigs can be a little hectic to set up. And if you do not use it a lot, you will have to re-learn how to set and use it every time.

The ease of use will also vary from one model and brand to the other.

#4. Cost

How much you are willing to pay for your dovetail jig determines the features that you get. For example, the more expensive variable dovetail jigs are more versatile and also offer a lot of features.

Tips on Using a Dovetail Jig

Here are some practical tips that will allow you to use the dovetail jig more effectively.

- Tightness: The depth of cut usually dictates if a dovetail joint is either too loose of too tight. You will need to have an accurate and standard depth of cut for all your joints. This can be achieved by properly adjusting your dovetail jig, especially if you are using a variable dovetail jig.

- Shallowness: Sometimes the pins might not fit properly into the sockets. If this happens, adjust the jig so as it moves towards the back of the body of the dovetail jig.

- Offset: Edges sometimes are not flush. In this situation, adjust the alignment of the stops on your jig. Proper measurement is key if you want to get an accurate and professional result with your dovetail jig.

- Cut the pin first: It is a good practice to cut the tails first before the pins. It is easier to shave away the pins so as the tails can fit rather than the other way round.

- Note down your measurement: When you make the perfect dovetail joint, remember your dovetail jig measurement so that you can quickly reproduce the same result elsewhere at another time.

Conclusion

As a woodworker, there are many projects that will require you to join two pieces of stock. Whether you are making cabinet or shelving for the kitchen you need to make some joints.

And when it comes to making joint the dovetail jig is one of the most useful things to have around. With this jig, making joint should be quick and easy.

Also, the dovetail jig allows you to make different kinds of joints to suit different projects or to bring out different appearances.

However, there are various models and brands of dovetail jigs in the market and our dovetail jig reviews and buying guide will make it easy to chose between them. But, the bottom line is always to go for the most versatile and the best dovetail jig that you can afford.

Image: woodworkersjournal.com; Reference: dovetailjigreviews.com (1, 2, 3), wwgoa.com

Last Updated on March 13, 2019 by Tom Bradly